CNC Machining & Digital Fabrication Services in Toronto

Precision. Power. Possibility.

CXC’s CNC and digital fabrication services bring bold ideas to life — from one-off showpieces to full-scale buildouts. Whether you’re a brand, an agency, or a fabrication shop looking for backup, we deliver complete, high-quality solutions with speed, precision, and craftsmanship. When the project demands more, we help you build bigger, smarter, and better.

What is Digital Fabrication?

-

CNC (Computer Numerical Control) machining uses computer-controlled tools to cut, carve, and shape materials with extreme precision and repeatability. By automating the process, CNC allows us to produce highly detailed components, custom millwork, and complex designs faster and more accurately than traditional fabrication methods.

-

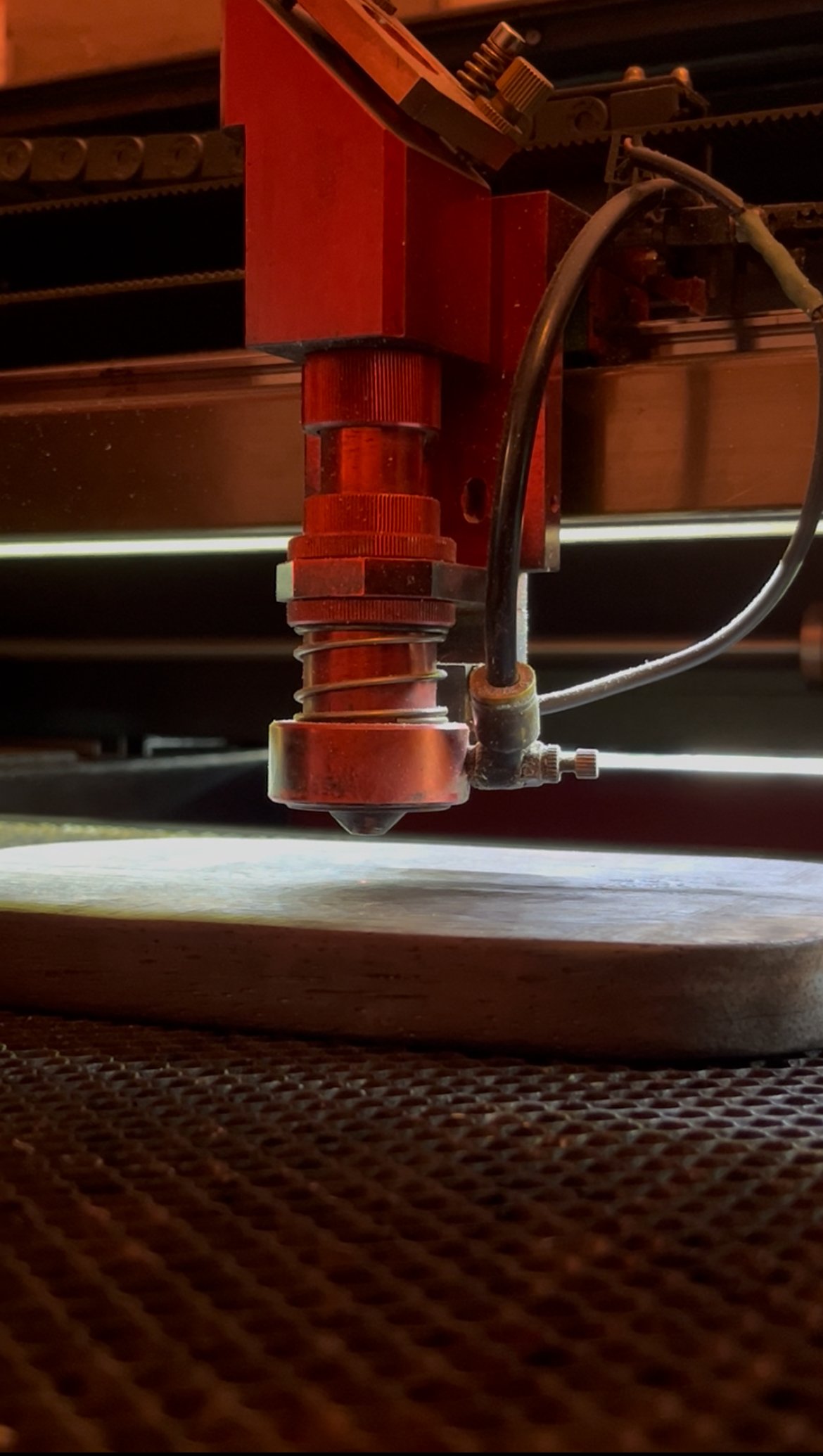

Laser cutting and engraving use a high-powered, computer-controlled laser beam to precisely cut, etch, or engrave materials. This process allows us to create intricate designs, detailed engravings, and clean, accurate cuts across wood, acrylic, and other materials — perfect for signage, branding, and custom fabrication work.

-

3D printing is a digital fabrication process that builds objects layer by layer from a computer-generated design, allowing us to create custom parts, prototypes, and complex geometries that would be difficult or impossible to produce using traditional methods. At CXC, we use 3D printing to rapidly prototype, test designs, and produce highly detailed, functional components that integrate seamlessly into our millwork and fabrication projects.

Advanced Tools. Flawless Results.

Our CNC machining, laser cutting, and 3D printing capabilities let us prototype, fabricate, and deliver projects with unmatched accuracy and speed.

Why Choose CXC for CNC Machining?

At Construct X Create (CXC), CNC machining is more than just cutting material — it’s the precision engine behind our most ambitious builds. From custom furniture to large-scale commercial installations, our in-house CNC and digital fabrication capabilities give us the accuracy, speed, and flexibility to bring complex concepts to life.

Advanced Precision

Our CNC routers can cut, carve, and mill with tolerances down to fractions of a millimeter — ensuring perfect fit and finish for even the most intricate designs.

Complex Problem-Solving

We excel at the challenging projects other shops won’t touch. Whether it’s a unique joinery detail, complex curve, or large-scale multi-part build, we engineer practical, beautiful solutions.

From Prototype to Production

We offer rapid prototyping to test designs before committing to full production, ensuring efficiency and cost-effectiveness for your project.

Material Versatility

We work with hardwood, plywood, MDF, acrylic, solid surface, foam, and specialty composites to suit your project’s requirements.

Seamless Design Integration

Our CNC machining works hand-in-hand with our millwork and fabrication teams, ensuring every component is engineered to fit perfectly within the overall design. This collaborative approach reduces errors, speeds up installation, and elevates the final result.

Large-Scale Capability

From small, detailed components to oversized panels and multi-part assemblies, our CNC equipment and workflow are built to handle projects of any scale—ideal for flagship retail, hospitality environments, and high-profile event builds.

FAQs

-

CNC machining uses computer-controlled tools to cut, carve, and shape materials with extreme accuracy. It’s ideal for complex designs, repeatable precision, and creating parts that fit perfectly the first time.

-

We machine hardwood, plywood, MDF, acrylic, solid surface, foam, and specialty composites. If your project requires a unique or challenging material, we’ll engineer the right solution.

-

No. We work on everything from one-off prototypes to full-scale production runs, including detailed components, custom furniture, architectural millwork, and large installations.

-

Absolutely. While we’re based in Toronto’s Stockyards, we’ve completed projects across Canada for brands, events, and productions.